Educational 3D Printer for Hands-On STEM Learning

The JellyBOX 4 DIY Kit revolutionizes STEM education with its unique,reusable 3D printer design, specifically tailored for repetitive builds.

-

JellyBOX 4 DIY Kit Contents

Over 500 components including 3D printer parts, precision laser-cut elements, fasteners, electronics, tools, and a comprehensive guide.

-

Collaborative Building Experience

Encourages teamwork; suitable for 1 to 3 students per printer.

Recommended 4 to 6 printers per class, for 4 to 18 students.

-

Minimum Age

11-12 years (7+ in settings with adult supervision).

Assembly time: 5 to 7 hours, varies by age and technical skill.

-

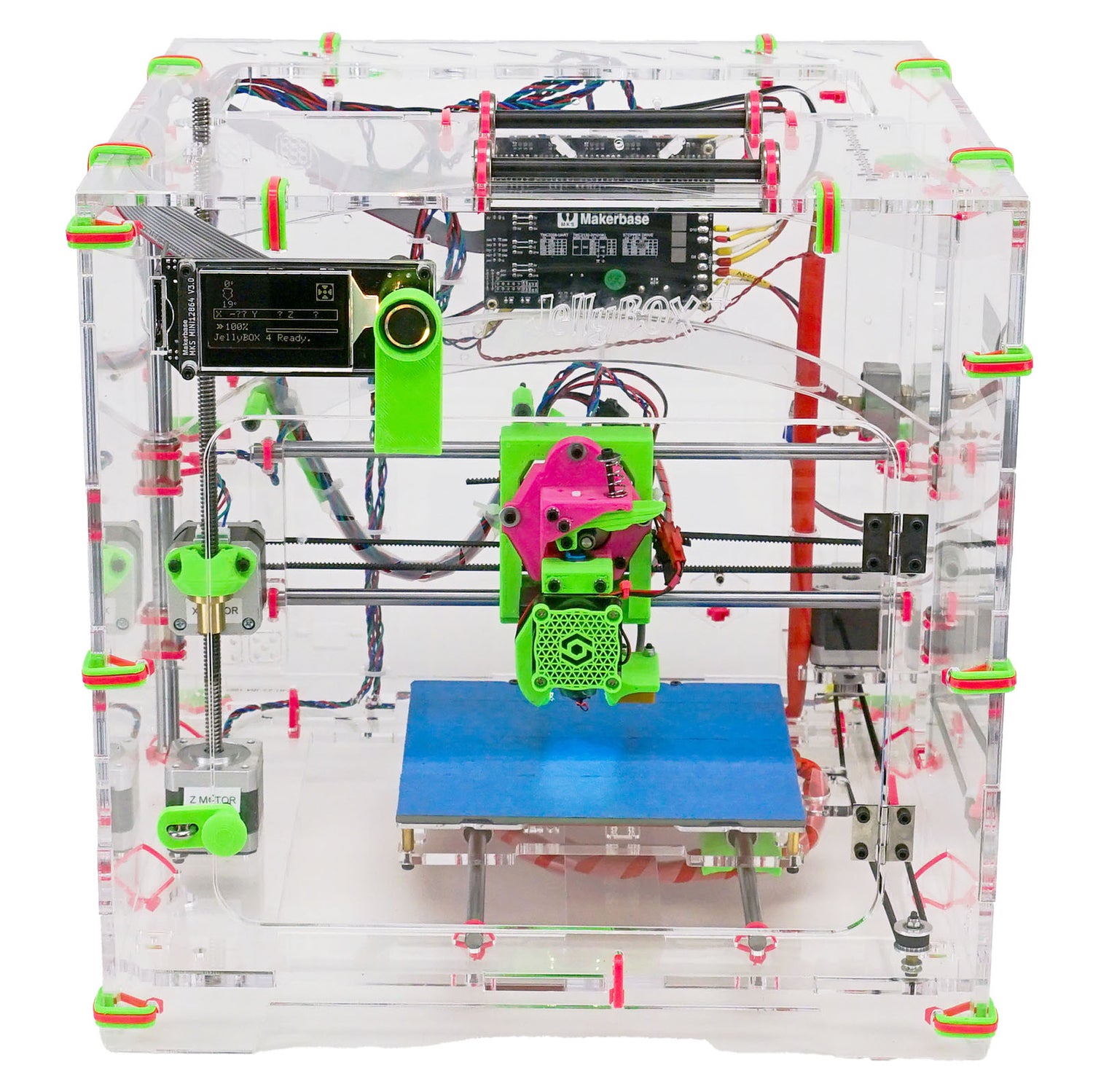

Transparent Acrylic Frame

The JellyBOX 3D printer’s transparent acrylic frame allows students to see all its internal workings, providing a clear view of how 3D printing functions.

-

Build, Learn, Repeat

The JellyBOX 3D printer's frame, held together by cable ties, can be easily assembled and disassembled.

This allows students to repeatedly build and rebuild the printer, providing a hands-on learning experience for multiple classes.

-

Educational Impact

Supports STEM, after-school programs, summer camps, and enrichment programs.

Promotes practical skills, understanding of 3D printing technology, and peer mentoring.

Discover why JellyBOX stands out as the ultimate 3D printer for your classroom:

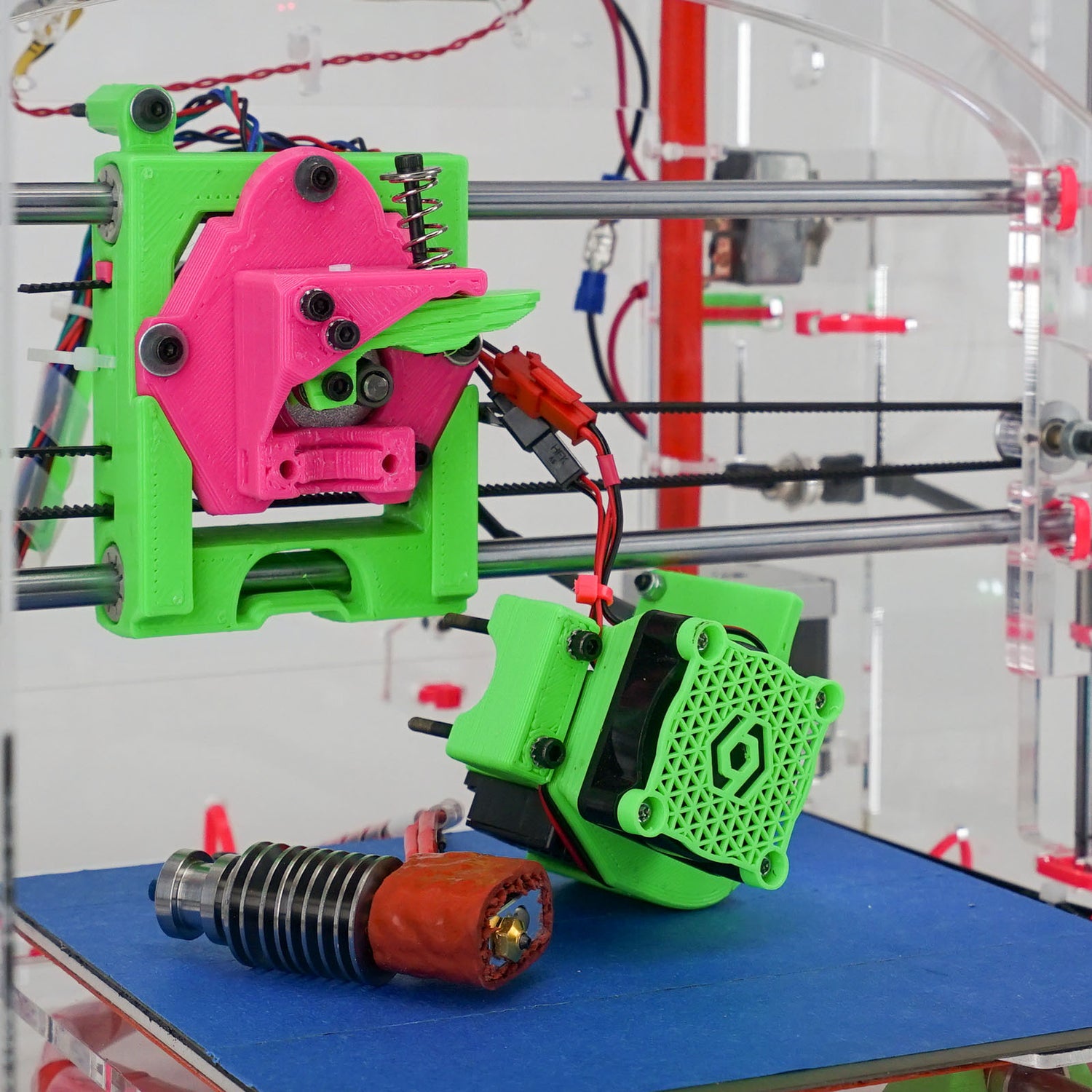

Effortless Nozzle Maintenance

With JellyBOX, a clogged nozzle is a one-minute fix, not a class disruption. Quick swap technology means no disassembly, no downtime, and no hassle.

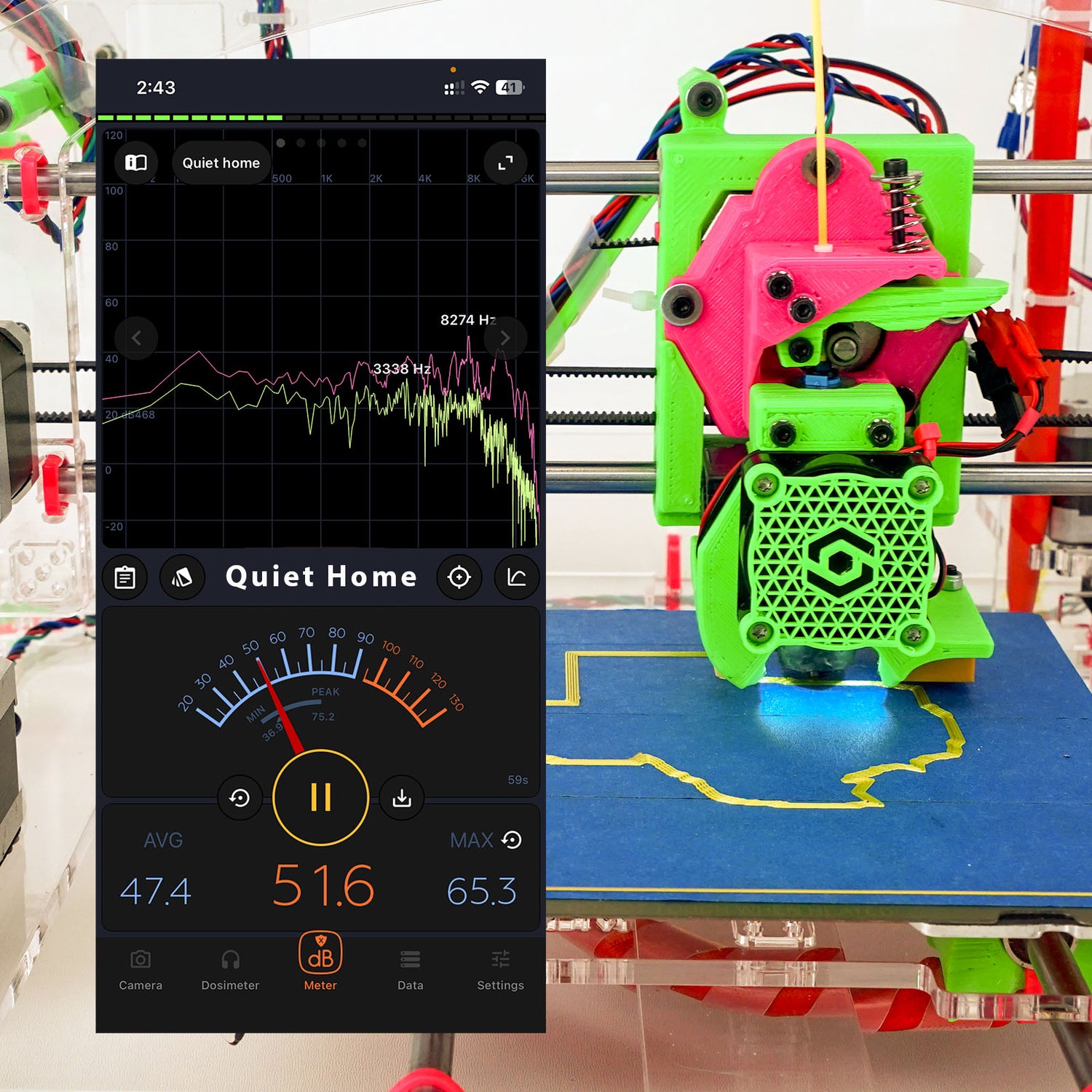

Whisper-Quiet Operation

Keep the focus on learning, not on noise. JellyBOX operates so quietly that multiple printers can run simultaneously without disrupting your lesson.

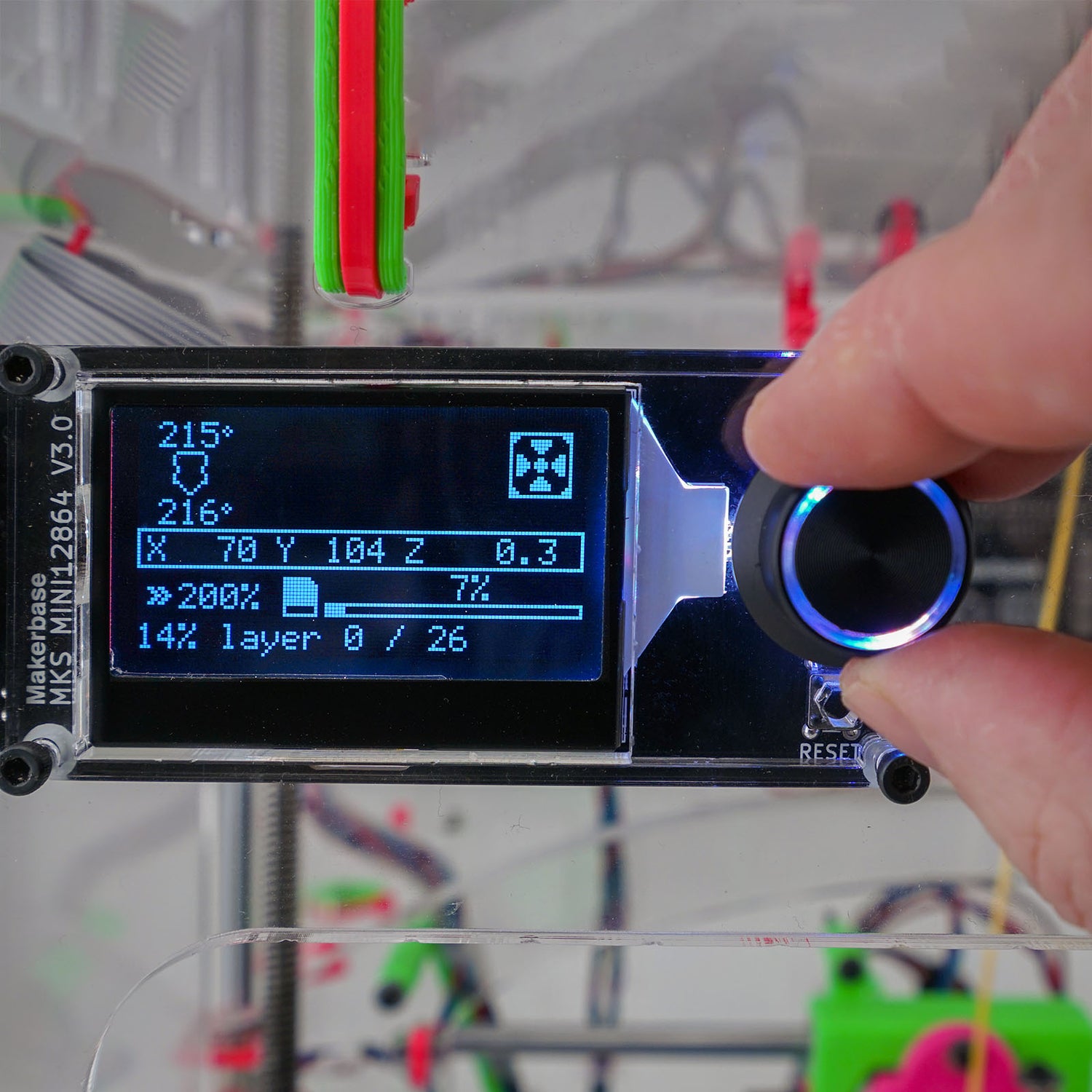

Accelerated Printing

Capitalize on JellyBOX's robust build and cutting-edge anti-vibration technology to print at speeds up to three times faster than standard 3D printers—transforming hour-long projects into 20-30 minute tasks

Unparalleled Material Versatility

From PLA, PETG to TPU, JellyBOX accepts a diverse range of filaments from any supplier. Embrace the freedom to use any standard spool, regardless of width or diameter.

Safe and Visible Design

The transparent acrylic enclosure ensures students can observe every stage of the printing process without risk, with optional locking for secure, unattended operation.

Seamless Learning with Cross-Platform Compatibility

Seamless Learning with Cross-Platform Compatibility

The JellyBOX curriculum encompasses assembly, slicing, 3D modeling, and printing. Leveraging browser-based, free software, it ensures a consistent experience across various platforms, including Windows, macOS, ChromeOS, and Linux. This eliminates the need for software installation on student devices while fully equipping them with essential 3D printing skills.

Technical Specifications

| Feature | Specification |

| Build Volume | 180 x 160 x 150 mm ( 7 x 6.3 x 5.9 inch) |

| Layer Resolution | 50 - 300 microns (for 0.4 mm nozzle) |

| Nozzle Diameter | coming with 0.4 mm nozzle, optional 0.3 mm - 1 mm |

| Bed | Heated, flexible steel with PEI surface, magnetic hold |

| Bed Leveling | Automated, using induction proximity sensor |

| Max. Nozzle Temperature | 280°C. ( 536 F) |

| Max. Bed Temperature | 90°C ( 194 F) |

| Filament Diameter | 1.75 mm |

| Filament Producer | Any, non-proprietary |

| Filament Spool Width | Max. 100 mm |

| Filament Spool Outside Diameter | Min. 140mm, Max. 260 mm, for filaments 0.25 kg - 5 kg |

| Print Speed | Up to 150mm/s utilizing Input Shaping technology |

| Printable Materials | PLA, PETG, TPU and others except ABS |

| Printing From | SD card, no computer is required for printing |

| Supported Files | Standard GCODE from all known slicers, like KIRI:MOTO, Prusa, Cura, Simplify 3D, etc. |

| Firmware | IMADE3D clone of the MARLIN 2.X |

| Machine Weight | 9 kg |

| Machine Size | 370 x 370 x 370 mm |

| Enclosure | Closed, from transparent acrylic with lockable doors |

| Safety Features | Nozzle and bed overheat protection |

| Power | AC 110-240V, 50-60Hz output DC 12V / 10A |